Brass Covers for Floor Socket Boxes

Die-Cast Brass Pump Body

Brass Valve Handwheel

Brass Parts Kit for Drop-Out Fuse

Custom Brass Casting Blanks

Brass Hose Fittings

Brass Sanitary Parts

Brass High Pressure Fittings

Brass Switch Panel

Brass Electrical Connectors

Brass Electrical Terminals

Brass Auto Parts

Brass Motorcycle Parts

Brass Furniture Handle

Brass Door Lock

Brass Furniture Hinge

Brass Window Door Bolt

Brass Furniture Brackets

Brass Door Stops

Brass Furniture Hardware Hook

Brass Door Knocker

Brass Casement Bolts

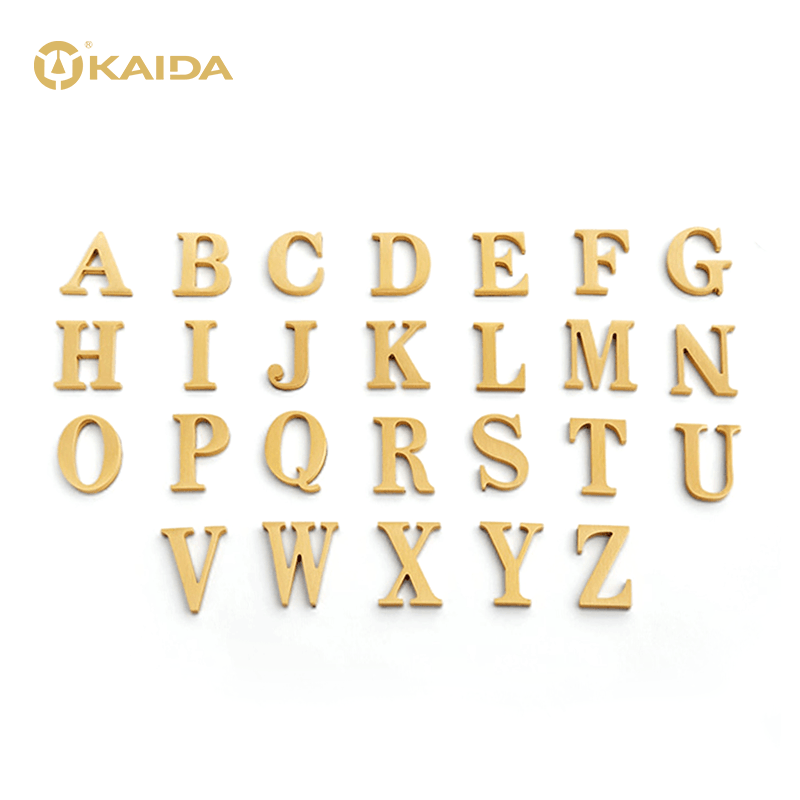

Brass House Letters

Brass Artware

Brass Coaster

Brass Frame

.png)

Brass Flower Art

Brass Funeral Supplies

Brass Floor Drain

Brass Bathroom Shower

Brass Bathroom Faucet

Brass Bathroom Angle Valve

Brass Towel Racks

Brass Bathroom Parts

Brass Parts Industry Knowledge Extension

Can Brass Parts be cast?

Yes, brass parts can be cast. Brass is a popular material for casting due to its low melting point and excellent fluidity when molten, which allows it to be easily poured into intricate molds to create complex shapes.

Brass casting is typically done using sand casting or investment casting methods. Sand casting involves creating a mold using sand and a pattern, then pouring molten brass into the mold. Investment casting, on the other hand, involves creating a wax pattern of the desired part, coating it in ceramic, and then melting the wax out before pouring the brass into the ceramic shell.

After casting, the brass part may undergo additional finishing processes such as machining, polishing, or plating to achieve the desired final shape and surface finish.

How does Brass Parts handle rust prevention?

Brass is an alloy of copper and zinc and is known for its resistance to corrosion, which makes it an ideal material for use in many applications where rust prevention is required. However, brass can still be susceptible to tarnishing and discoloration over time due to exposure to air and moisture.

To prevent brass parts from tarnishing and discoloration, a few different techniques can be used:

Coating: A protective coating can be applied to the surface of the brass parts to prevent them from reacting with the air and moisture. A common coating material for brass parts is clear lacquer, which provides a protective barrier and a glossy finish.

Polishing: Regular polishing of the brass parts can help to remove any tarnish that has formed and restore the original shine. This can be done using a brass polish and a soft cloth.

Storage: Storing brass parts in a dry environment with low humidity can help to prevent tarnishing and discoloration over time.

Preventing Contact with Other Metals: Brass parts should be kept away from other metals, particularly those that are more reactive, as this can cause a reaction that leads to tarnishing and corrosion.

By following these techniques, brass parts can be effectively protected against rust and corrosion, ensuring that they maintain their appearance and functionality over time.

How to turn the processed brass parts into bright yellow

The natural color of brass is a shiny golden color, but over time it can become tarnished or discolored due to exposure to air and moisture. To restore the bright yellow color of processed brass parts, you can use one of the following methods:

Polishing: Polishing the brass parts can remove any tarnish or discoloration and restore their original shine. You can use a brass polish and a soft cloth to gently rub the surface of the brass until it becomes bright and shiny.

Electroplating: Electroplating is a process that involves coating the surface of the brass with a thin layer of a different metal, such as gold or silver, to improve its appearance and protect it from tarnishing. Electroplating can be done by a professional service or by using a home electroplating kit.

Lacquering: Applying a clear lacquer coating to the surface of the brass parts can protect them from tarnishing and maintain their bright yellow color over time. The lacquer provides a protective barrier that prevents air and moisture from reaching the brass surface and causing discoloration.

It's important to note that these methods will only work if the brass parts have not been coated with a protective layer or if that layer has been removed prior to applying any of these methods. Additionally, the brass parts may need to be cleaned before applying any of these methods to ensure that the surface is free of dirt and grime.

EN

EN

西班牙语

西班牙语