Who We Are

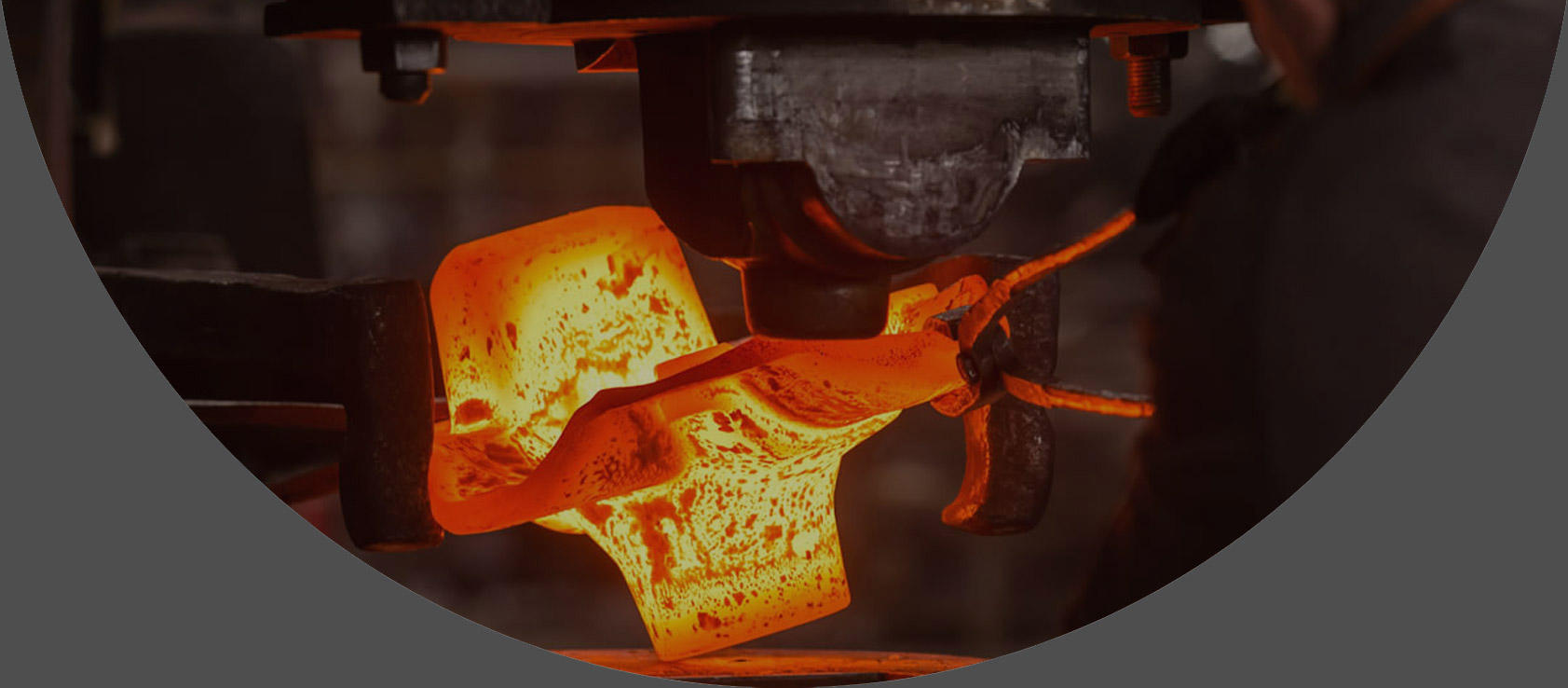

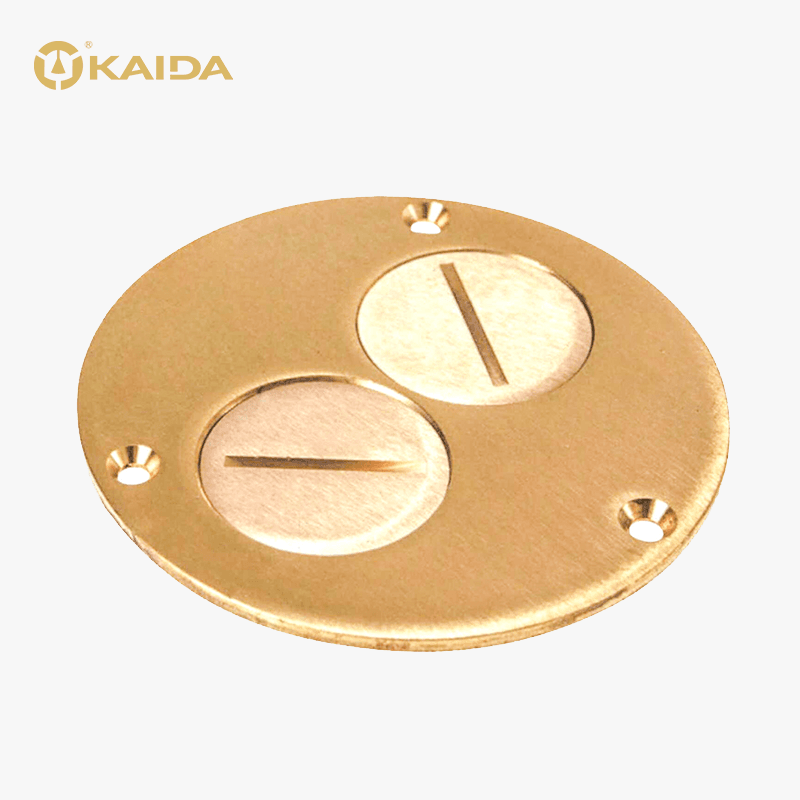

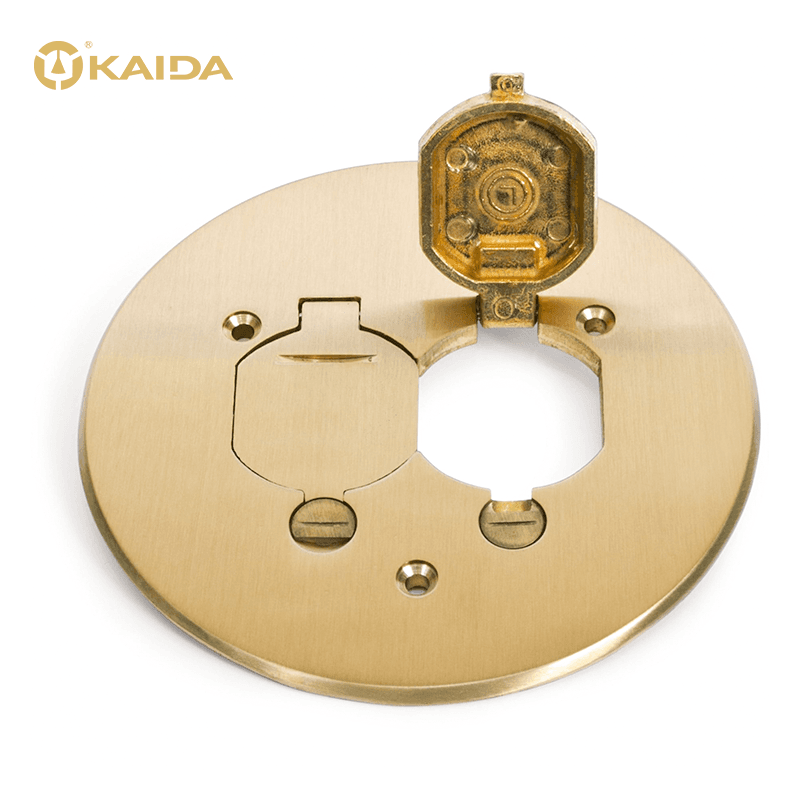

casting and forging of copper parts, and its product types and customized parts

.-

Complete company management system

-

Diversified product categories

-

Strong technical advantages and quality management system

-

0+

Factory cover(M2)

-

0+

Industry experience

-

0+

Employees

-

0+

Annual output(tons)

EN

EN

西班牙语

西班牙语