What are the advantages and disadvantages of Brass High Pressure Fittings compared to high pressure fittings made of other materials?

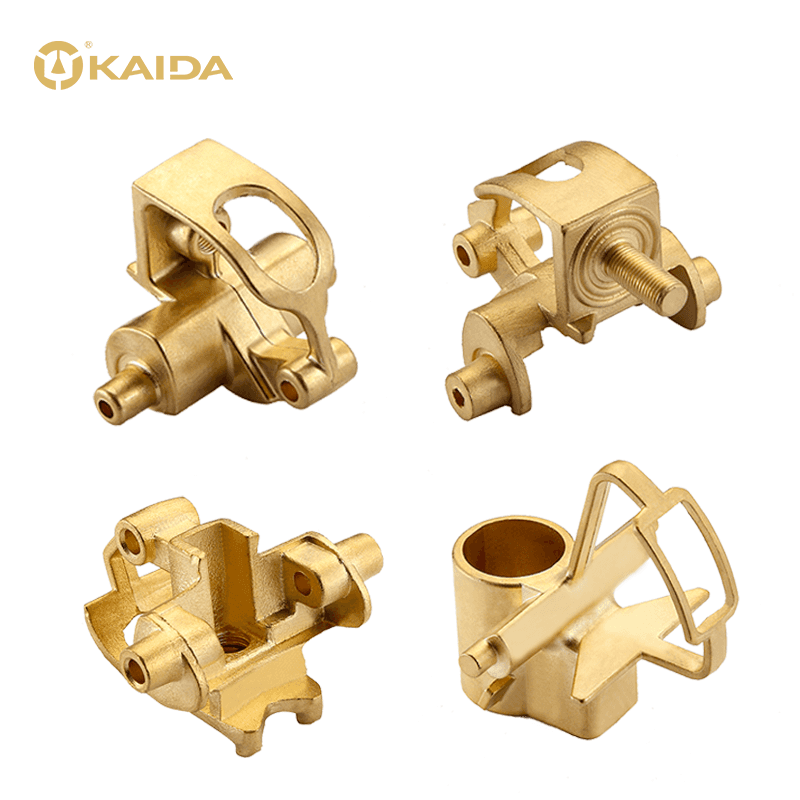

Compared with high-pressure fittings made of other materials, the advantages and disadvantages of Brass High-Pressure Fittings are as follows:

Advantage:

1. Strong corrosion resistance: Brass has good corrosion resistance, can be used in humid and corrosive environments, and is not easy to rust.

2. Good thermal conductivity: Brass has good thermal conductivity, can quickly dissipate heat, and is not easily affected by thermal expansion.

3. Good high temperature resistance: Brass has good high temperature resistance and can be used in high temperature environments.

4. High strength: Brass has good mechanical strength and can withstand certain pressure and tension.

Disadvantages:

1. Large specific gravity: Brass has a large specific gravity and is relatively heavy compared to other materials.

2. Relatively high cost: Compared with other common materials, the cost of brass materials is high.

3. Not suitable for some special environments: Brass cannot be used in some special environments, such as acid-base environments, etc., because it is easily corroded and oxidized.

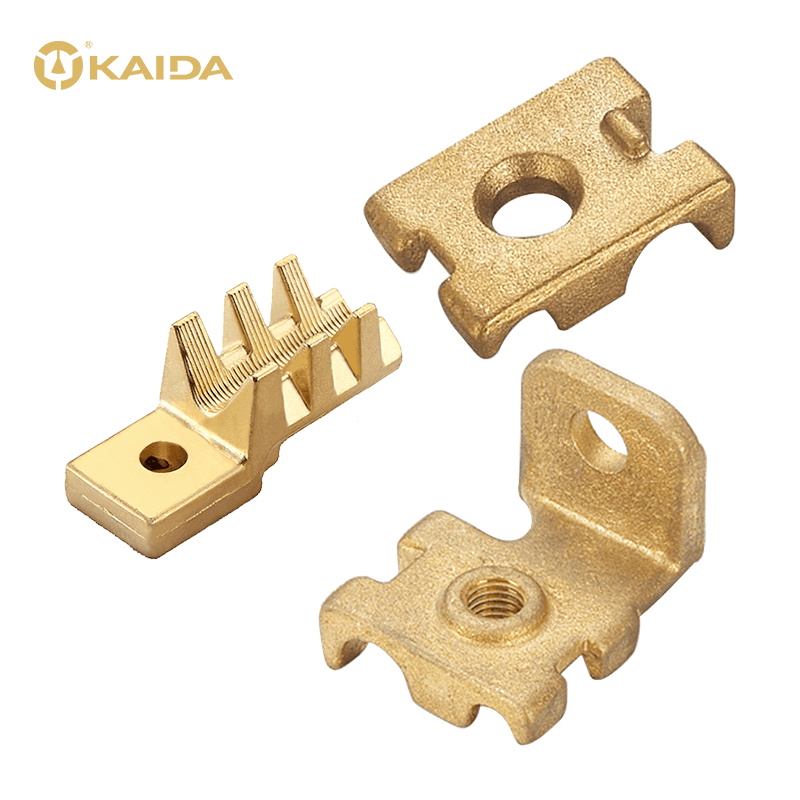

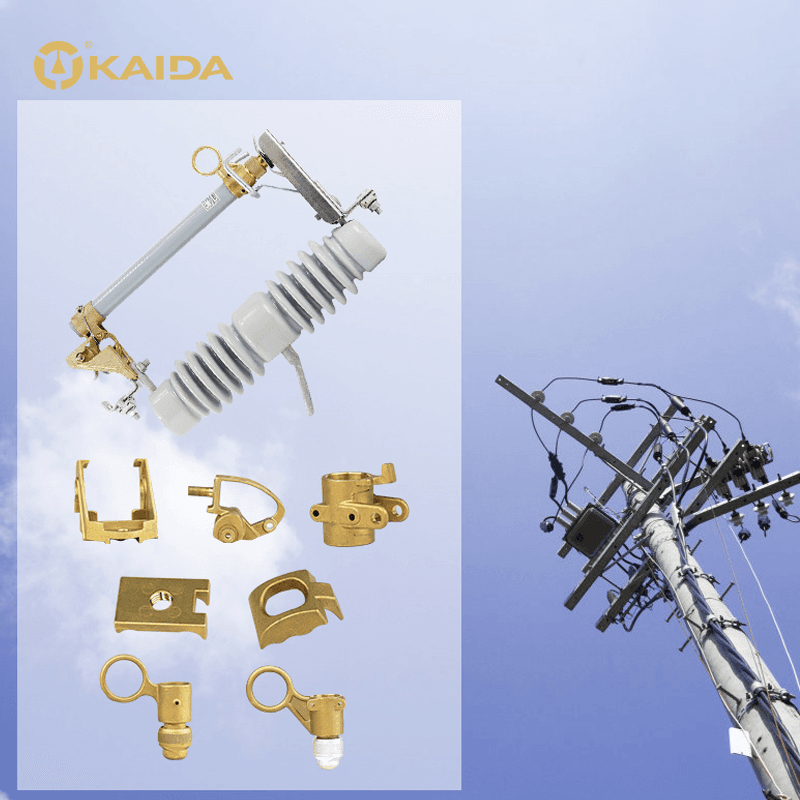

How are Brass High Voltage Fittings Fuses evaluated and tested for life and performance?

Evaluating the life and performance of Brass High Voltage Fittings Fuses requires the following tests:

1. Electrical performance test: test Brass High Voltage Fittings Fuses electrical performance indicators such as breaking capacity, temperature rise, and discharge voltage at rated voltage.

2. Temperature Test: Tests the temperature rise of Brass High Voltage Fittings Fuses at rated voltage and performance at extreme temperatures.

3. Mechanical performance test: Test the mechanical performance indicators of Brass High Voltage Fittings Fuses such as vibration resistance, corrosion resistance and wear resistance.

4. Life Test: Use Brass High Voltage Fittings Fuses for extended periods of time to see how their life and performance change.

5. Safety performance test: test Brass High Voltage Fittings Fuses' fire performance, explosion-proof performance and other safety performance indicators.

All the samples of our Brass High Voltage Fittings Fuses passed the above tests.

What are the benefits of using high-pressure brass fittings?

High-pressure brass fittings offer several advantages in various applications. Firstly, brass is a durable and corrosion-resistant material, making it ideal for withstanding high-pressure environments. The strength and reliability of brass fittings ensure leak-free connections, providing enhanced safety and performance.

Additionally, brass fittings have excellent thermal conductivity, allowing for efficient heat transfer. This is particularly beneficial in applications where temperature control is crucial, such as heating systems or industrial processes.

Another advantage is the versatility of high-pressure brass fittings. They are compatible with a wide range of fluids, including water, oil, and gas, making them suitable for various industries, including plumbing, HVAC, and automotive.

Furthermore, brass fittings are easy to install due to their malleability and machinability. They can be quickly and securely connected using various methods, such as compression or threaded connections.

Lastly, high-pressure brass fittings are cost-effective compared to other materials without compromising on performance and durability. Their longevity and resistance to wear and tear ensure long-term reliability and reduced maintenance costs.

The use of high-pressure brass fittings offers durability, corrosion resistance, thermal conductivity, versatility, ease of installation, and cost-effectiveness, making them a preferred choice in high-pressure applications.

EN

EN

西班牙语

西班牙语