Brass Fuse Cutout Pull Ring

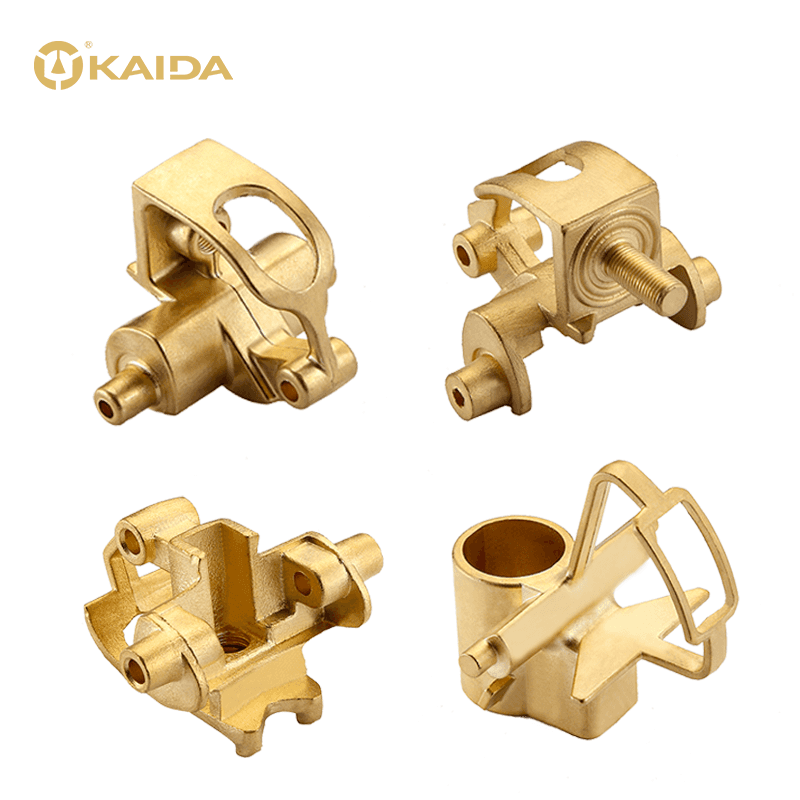

Brass Fuse Cutout Hinge

Brass Fuse Cutout Lower Socket

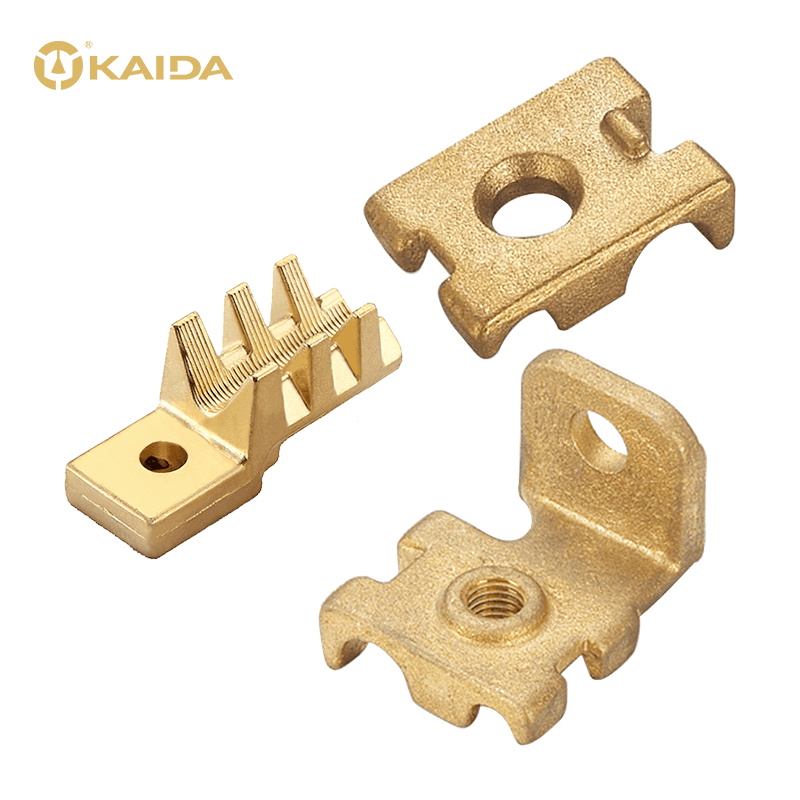

Brass Fuse Cutout Lower Contacts

Brass Fuse Cutout Upper Contacts

Brass Fuse Cutout Connector

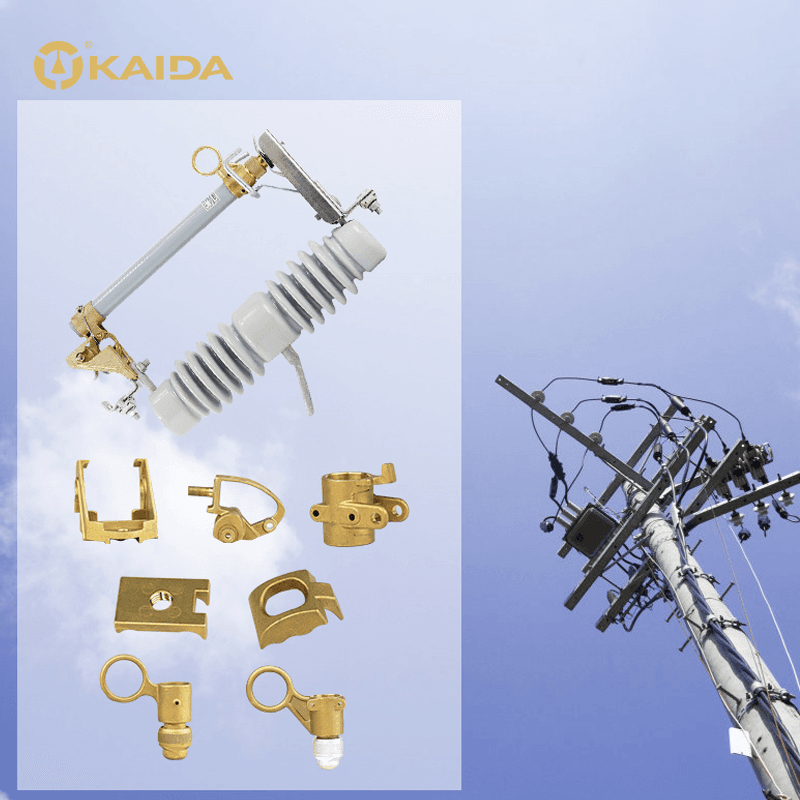

Brass High Voltage Fuse Cutoute

Brass High Voltage Fuse Cutoute

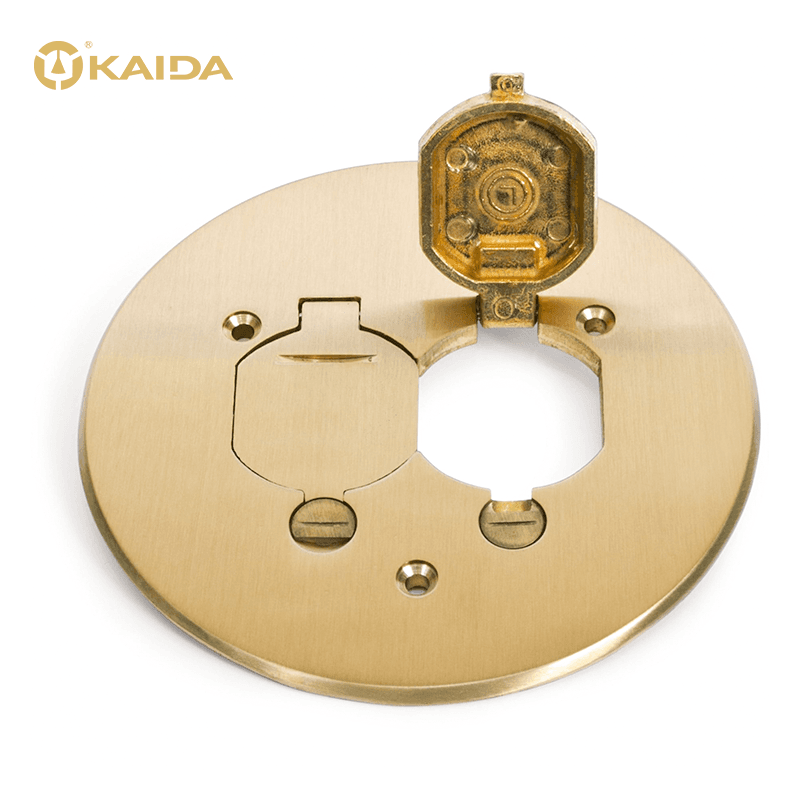

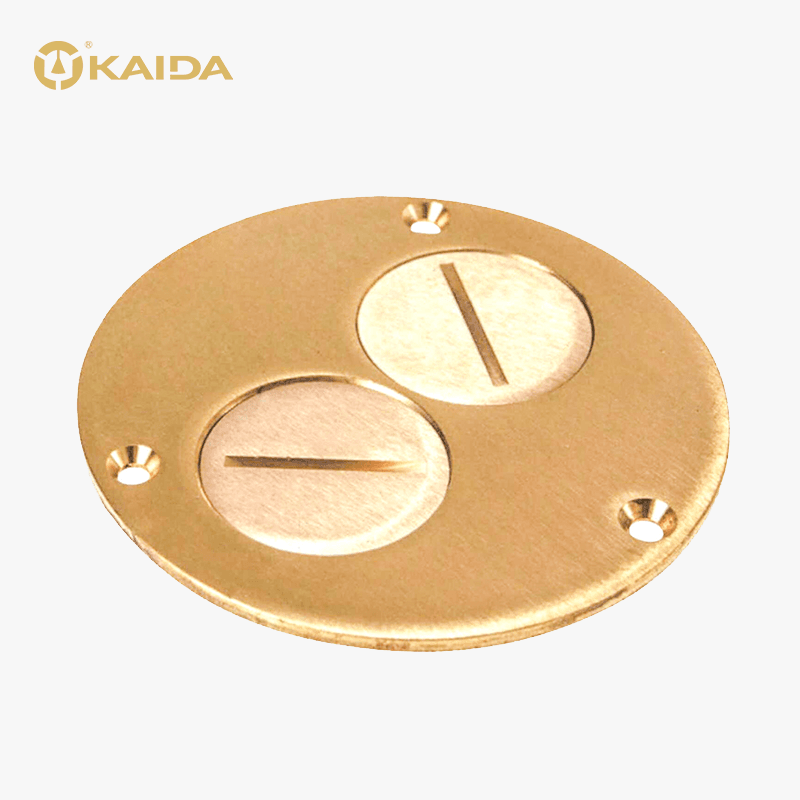

Brass Floor Box Covers

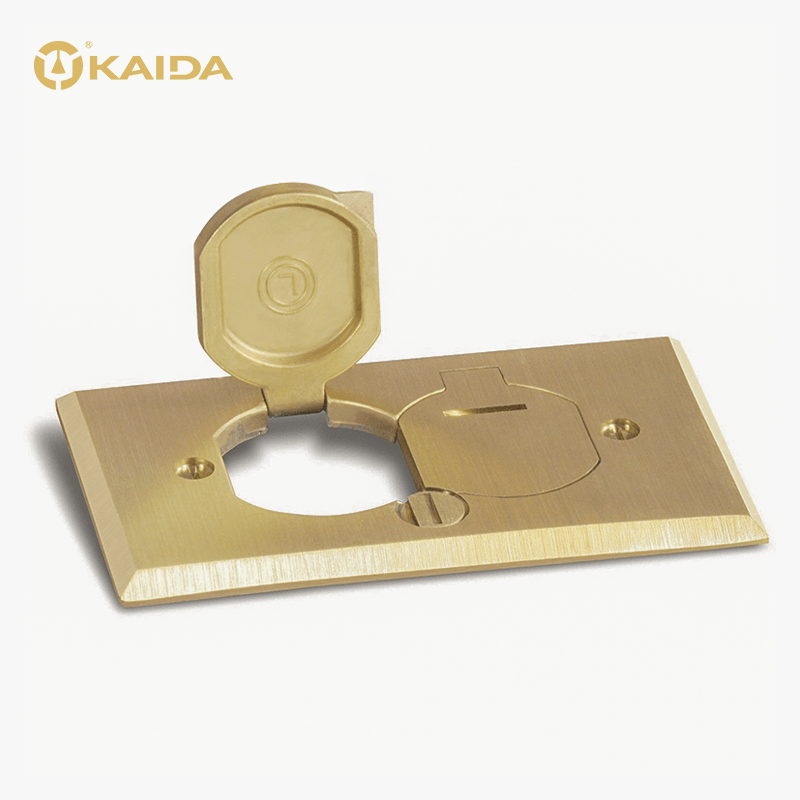

Brass Floor Electrical Box

Brass Electrical Boxes Panels

Brass Contact Pin and Socket

Brass Terminal Bars

Brass Electrical Parts Industry Knowledge Extension

What are the advantages and disadvantages of Brass Electrical Parts compared with electrical parts made of other materials?

Brass is a popular material choice for electrical parts due to its excellent electrical conductivity, corrosion resistance, and ease of machining. However, there are also some disadvantages to using brass electrical parts. Here are some of the advantages and disadvantages of using brass electrical parts compared to other materials:

Brass is a popular material choice for electrical parts due to its excellent electrical conductivity, corrosion resistance, and ease of machining. However, there are also some disadvantages to using brass electrical parts. Here are some of the advantages and disadvantages of using brass electrical parts compared to other materials:

Advantages:

Excellent Electrical Conductivity: Brass is an excellent conductor of electricity, which makes it an ideal material for electrical parts. It has a conductivity rating of 28% IACS (International Annealed Copper Standard) which is comparable to that of copper.

Corrosion Resistance: Brass has a natural resistance to corrosion, which makes it suitable for use in harsh environments. This property makes it useful in marine and coastal areas where the air contains salt particles.

Easy to Machine: Brass is easy to machine due to its low melting point and softness. This makes it easy to shape and create intricate parts.

Low Friction: Brass has a low coefficient of friction, which means it is easy to work with and can withstand repeated use without breaking down.

Disadvantages:

Expensive: Brass is more expensive than some other materials such as plastic or steel. This can make it difficult for businesses to justify using it in large quantities.

Heavy: Brass is heavier than some other materials, which can make it difficult to use in certain applications.

Oxidation: Although brass is corrosion-resistant, it can oxidize over time, leading to discoloration and reduced conductivity.

Not Suitable for High Temperatures: Brass has a low melting point, which makes it unsuitable for use in high-temperature environments.

Overall, brass electrical parts are a good choice for many applications due to their excellent electrical conductivity and corrosion resistance. However, the higher cost and weight may make them less desirable in certain situations. Additionally, they may not be suitable for high-temperature environments, and care should be taken to prevent oxidation.

As a metal, brass electrical parts have safety hazards when they are used?

Brass electrical parts are safe under normal use. Brass itself is a metal material with good electrical and thermal conductivity, which has the following advantages in the manufacture of electrical components:

Corrosion Resistance: Brass is highly resistant to oxidation and corrosion, allowing brass electrical parts to withstand long-term use in wet and corrosive environments.

Good electrical conductivity: Brass has excellent electrical conductivity, allowing electric current to flow smoothly through electrical parts.

High Wear Resistance: Brass electrical parts are highly wear resistant and able to withstand friction and wear.

However, brass electrical parts can also be a safety hazard if they are mishandled or installed. For example, when installing a brass socket or switch, if the power is not turned off, it may cause an electric shock accident. Therefore, when using brass electrical parts, you should follow the correct installation method and pay attention to safety.

What are the benefits of using industrial electrical brass accessories?

Industrial electrical brass accessories offer several advantages in various applications. Firstly, brass is a highly durable and corrosion-resistant material, making it suitable for use in demanding industrial environments. The superior conductivity of brass ensures efficient electrical transmission, reducing power loss and optimizing performance. Additionally, brass accessories exhibit excellent heat resistance, enabling them to withstand high temperatures without deformation or degradation. The malleability of brass allows for complex and precise component designs, ensuring compatibility with different electrical systems. Moreover, brass is a cost-effective option compared to other materials while maintaining high quality and reliability. The versatility of brass accessories makes them suitable for diverse electrical applications, including wiring, connectors, terminals, and grounding components. Overall, using industrial electrical brass accessories guarantees long-lasting performance, efficient electrical conductivity, and cost-effective solutions in various industrial settings.

EN

EN

西班牙语

西班牙语